Company

Over 100 employees work at SITEC worldwide to protect public buildings and human lives from break-ins, robberies, attacks, and fires. As part of the Clausen corporate group, SITEC is a family-owned business run by the founder’s family in its third generation. At its headquarters in Weißenbrunn in Upper Franconia, SITEC manufactures burglary and ballistic-resistant security systems such as transfer systems, glazed counters, intercom systems, personnel locks, and security doors and partition wall systems.

SITEC products are primarily used in banks, data centres, court houses, petrol stations, gatehouses, and government buildings around the world. SITEC continuously develops these products to meet the constantly changing security requirements.

All products are developed and constructed within the corporate group. From metal processing with state-of-the-art machinery, through electronics manufacturing and software development, to on-site assembly, the various production steps are carried out by SITEC itself to fulfil the quality promise of “Made in Germany”.

Our company history

In 1954, Kiel interior designer Heinz Clausen founded a small carpentry business in Thonberg near Kronach in Upper Franconia. The small company was involved in interior fittings and shop fitting. Using the simplest means and with two employees, furniture and installations were designed, produced, and installed for local commerce.

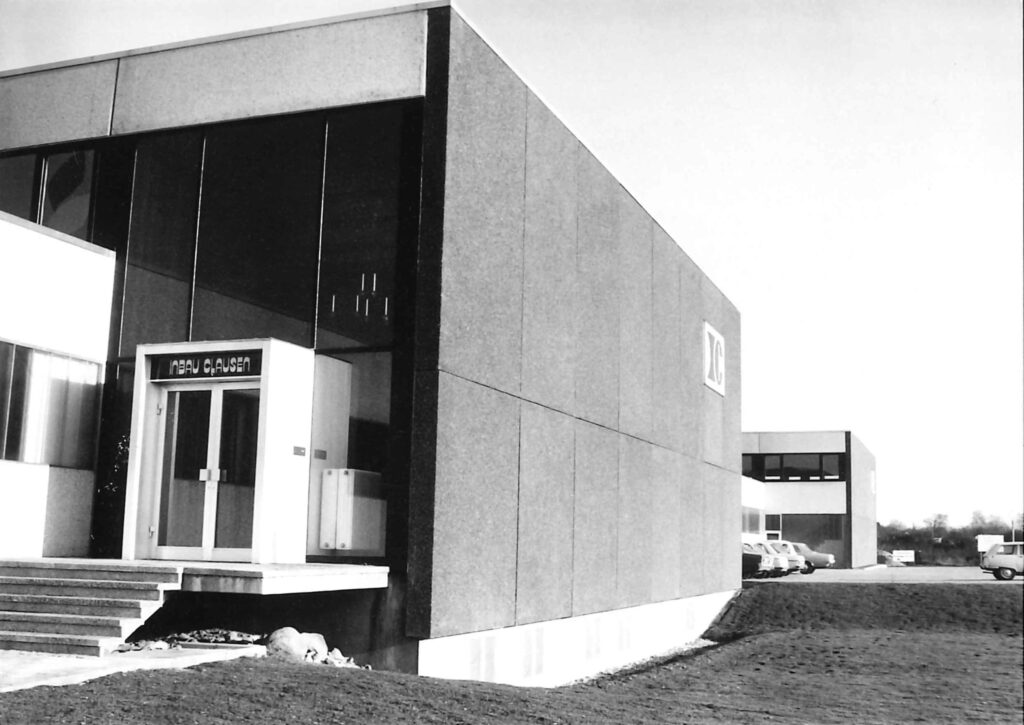

When the rented premises became too small, a new facility was built in 1960 a few kilometers away at the current location in Hummendorf for 25 employees.

By the end of the 1960s and beginning of the 1970s, the company began to focus more on the northern German market and the interior fittings of ships. A new plant was built near Kiel, and the headquarters of Inbau Clausen was relocated there.

Due to the RAF terrorism and bank robberies of the 1970s, security solutions became increasingly necessary in shop fitting, prompting the Weißenbrunn site to specialize in the production of security technology.

In June 1975, SITEC GmbH was established, and Olaf Clausen's son took over the management.

In the years 1980 and 1985, production buildings were expanded, and metal processing was further developed.

In addition to equipping petrol stations and bank branches, increasing numbers of national and major banks were equipped. Especially the securing of currency processing in state central banks came into focus.

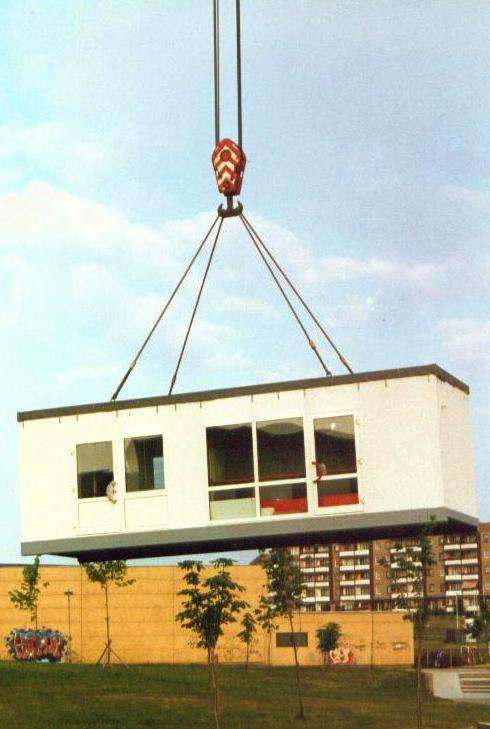

The fall of the Iron Curtain and the reconstruction in the East opened up new markets for SITEC, necessitating entirely new products. With the production of portable high-quality bank containers, including the security technology of a normal bank branch, SITEC supports the rapid expansion of the German banking sector into the new federal states.

The mobile banks are fully equipped in the plant and delivered turnkey, including ATMs.

In the years 1990 and 1996, both the company premises and office buildings were expanded. The hall rented for metal processing in the nearby town of Au was abandoned, and the newly constructed production hall at the headquarters in Hummendorf was occupied. The new building is specifically designed for producing heavy steel structures such as mobile banks and also provides space for a large small parts warehouse and assembly workplaces.

The product portfolio is expanded to include electronic locker systems for train stations - initially only as pure trading goods.

The Scottish company Locksafe becomes part of the corporate group in 1997 and transitions into LockTec Ltd. in Edinburgh.

At the Weißenbrunn site, LockTec GmbH is founded, which will henceforth take over the distribution of locker systems, which will then be manufactured by SITEC.

For more information, visit: https://www.locktec.com

In the aftermath of September 11, 2001, global security needs change. In the following years, SITEC increasingly outfits government buildings both domestically and abroad with security technology, including numerous German embassies and consulates.

As cashless payment transactions become more prevalent, the nature of personal banking changes. The elimination of closed cash counters and the increasing closure of bank branches also requires a rethinking in security technology.

SITEC responds with the electronic personnel lock AXXES. The biometric access control system enables secure access for a single person to a security area through fingerprint identification. The personnel locks are primarily used in bank branches and data centres.

The new warehouse and logistics hall for the corporate group is ready for occupancy. 750 m² of space is now available for incoming goods and material orders for large projects.

With the new portal milling machine PORTATEC, three-dimensional parts made of aluminium, plastic, insulating materials, composite materials, and wood-based materials are now also manufactured.

The new laser welding robot TruLaser Weld 5000 enables the semi-automatic manufacture of parts made of stainless steel, steel, and aluminium. The production of components is now even more precise and efficient.

The new profile processing centre also allows for a more efficient production of steel profiles.

The new machines also complement SITEC's contract manufacturing offering: https://lohnfertigung.sitec.de

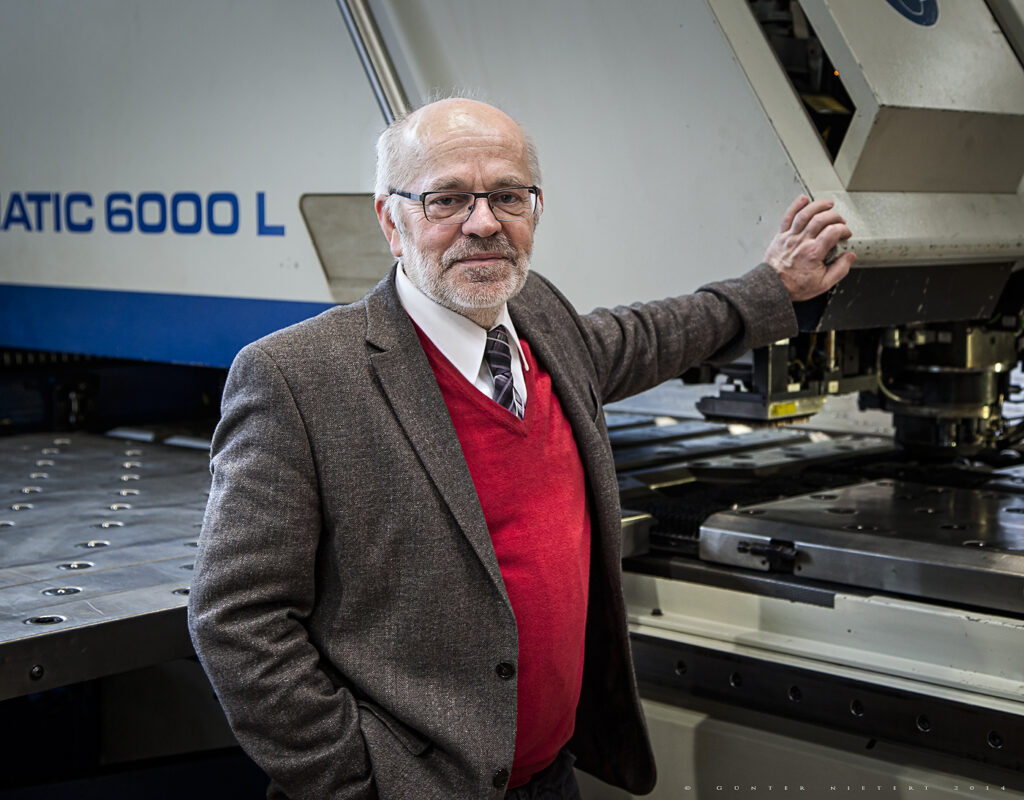

The sudden death of Olaf Clausen marks a profound change for the Clausen family and the corporate group. His sons Lukas and Johannes Clausen take over the management of the various companies.

The new precision bending press Easy-Form 220/40 Plus ensures greater productivity and precision in CNC bending.

The new grinding and deburring machine PT 1350 guarantees very good processing quality for our sheet metal parts.

The new welding robot allows for automated MAG welding with even better results.

For more information on our machinery, visit https://lohnfertigung.sitec.de/maschinenpark.

Due to the increasing diversity of products and the growing project business, additional storage space for project provision in the form of a tent and the extension of a sheet metal shelf hall is necessary.

As a result of Olaf Clausen's death, a restructuring of the company's structure is necessary. The companies LockTec and SITEC are now part of the Olaf Clausen GmbH & Co. KG.

In 2022, the corporate group begins the construction of a biomass heating plant and the associated wood chip storage as part of its sustainability strategy (see illustration). In addition to heat generation, a new combined heat and power plant also provides electricity for the buildings.

The punching-laser machine TruMatic 6000 fiber enables flexible, fast, and continuous production. It produces fully automated, high-quality, sustainable and versatile products.

Furthermore, capacities in metal processing have been expanded with a new bending machine TruBend 7050.

For more information on our machinery, visit https://lohnfertigung.sitec.de/maschinenpark.

The corporate group completes the biomass heating plant and processes pallet waste into wood chips for this purpose. Additionally, the group donates over 1,000 trees for the reforestation of the Franconian Forest.

For more information about the sustainability strategy, visit www.sitec.de/en/company/sustainability.

With the certification according to ISO 9001 and ISO 14001, SITEC demonstrates that a high-quality quality management system has been implemented. Furthermore, the company highlights its commitment to environmental protection and sustainability.